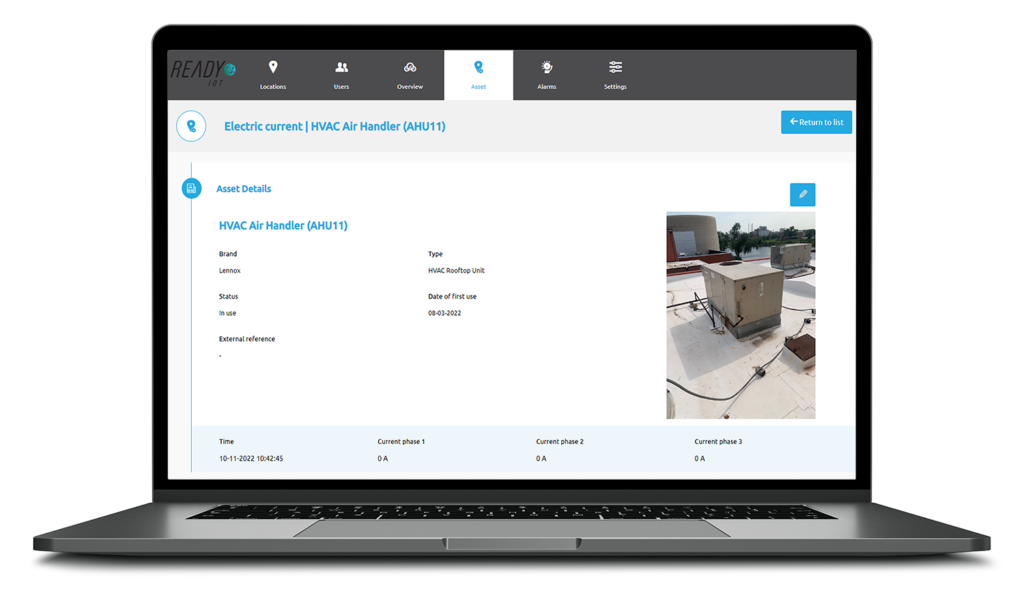

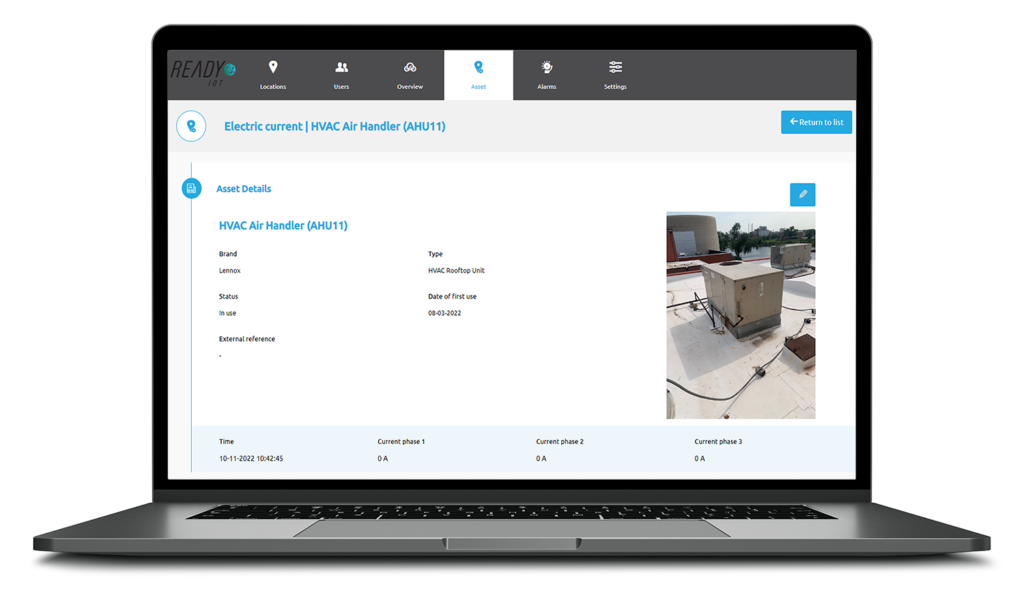

Welcome to The Ready Office! Our headquarters is a working IoT laboratory. Our 13,920-square-foot office in a 1923 building is the perfect playground to test the latest IoT devices. Gary Kreutner, Director of Service Solutions, explains our latest application for smart buildings – remote monitoring for air handlers.

Concerned about the performance of your air handling units (AHUs)? Try a wireless current meter that sends alerts whenever amperage fluctuates. It’s an easy way to remotely monitor your AHUs without ever having to step foot on the roof.

The Setup – Our 1960s AHU

Our AHU is from the 1960s with a 3-phase 208V motor from 1984. There is nothing “smart” about this legacy system. All readings have to be done by hand.

It’s also located on a hard-to-access roof. Because our building sits on a riverbank, there’s always a stiff breeze. Ladder safety is a concern even in the best weather conditions.

We wanted an IoT solution that could automatically monitor performance, especially for anomalies such as amperage fluctuations and power outages.

The Tech – Current Meter + Light Sensor

We were thrilled to find the NETVOX Wireless Light Sensor and 3-Phase Current Meter. It sends alerts whenever there’s an amperage deviation. These notices are how we achieve proactive maintenance rather than reactive repairs.

The meter is set to the motor’s full load amps (FLA) as a baseline reading. It then detects behavior that spikes above or below this norm. When power is outside of a certain boundary, there’s usually a problem that needs attention.

Examples of common AHU issues this sensor might catch:

- Faulty receptacle legs – One or more of the legs on a 120V motor will go bad over time, causing amperage to spike.

- Old motor bearings – As bearings age, they create resistance as the motor turns. This forces the motor to work harder, consuming more power.

- Belt problems – A belt that’s too tight will cause excessive amperage. This can lead to premature bearing failure, which is a costly replacement. Conversely, low amperage is a clue you might have a loose belt. Under-tensioned belts lead to slippage, overheating, excessive pulley wear, rollover, and noise, all of which lead to higher maintenance costs and inefficient power transmission.

The ambient light sensor is another bonus. If it surges, the AHU access panel has been breached. Maintenance might have not latched the door properly or wind blew it open during a storm. It could also be a sign that there’s been tampering.

Device Details

The NETVOX Wireless Light Sensor and 3-Phase Current Meter detects electrical input current and ambient light intensity. Reporting is in 15-minute intervals, with email or SMS alerts. It communicates via LoRaWAN.

Works on motors such as exhaust fans, sump pumps, distribution pumps, and generators. The device attaches with simple magnets. Batteries last for five years on average.

Results So Far

We installed the device in spring 2021. We had one notable incident when the amperage dropped – a loose belt was the culprit. Because we were able to make a quick repair, we didn’t have part damage, wasted energy, or additional maintenance problems.

The main benefit so far is peace of mind. We want to avoid a motor failure at all costs. Especially since we have a legacy unit, a replacement might be difficult to find or unreasonably expensive. A motor should run for 15-20 years with good maintenance, and we want to extend ours for as long as possible. The sensor allows us to stay on top of upkeep.

Our Review

The NETVOX Wireless Light Sensor and 3-Phase Current Meter is versatile and easy to use. We feel the main ROI comes from preventing catastrophic shutdowns. This one sensor can help avoid:

- emergency business closures

- costly service calls

- expensive replacement parts

We also like that this is a passive solution. Notifications are sent when needed, but otherwise there’s no babysitting or complicated dashboard. The data can be analyzed if you want to forecast trends, but the amperage alerts aren’t dependent on that step.

Chat with Gary!

Gary Kreutner is the Director of Service Solutions for Ready IoT. He previously spent 20 years as an Air Force civil engineer. Geek out with him at provisioningadmin@readywireless.com.